The Rise of Robotic Fulfillment Centers: Why the Future of Warehousing is Robot-Native

E-commerce fulfillment has reached a critical inflection point. With consumers now expecting delivery times measured in hours rather than days, traditional warehouse operations—even those with bolted-on automation—are struggling to keep pace. According to recent industry data, 61% of global consumers choose to shop with brands that can deliver their products fastest, making fulfillment speed a critical competitive advantage.

This shift has sparked a revolution in logistics: the emergence of the robot-native fulfillment center. Unlike traditional warehouses that simply integrate robots into existing workflows, robot-native facilities are designed from the ground up with robotic systems as their operational foundation. Every aspect—from the physical architecture to the software infrastructure—is built around robotic capabilities rather than human limitations.

OPLOG stands at the forefront of this transformation, having engineered its fulfillment ecosystem to be robot-native from inception. This strategic approach doesn't just add robots to existing processes; it reimagines logistics by making robotic workflows the core operational philosophy.

In this article, we'll explore what truly makes a fulfillment center robot-native, examine the concrete benefits this approach delivers, and look at how OPLOG's TARQAN exemplifies the future of robotic logistics.

Beyond Automation: What Makes a Fulfillment Center Truly "Robot-Native"

The distinction between automated warehouses and robot-native fulfillment centers isn't merely semantic—it represents a fundamental difference in design philosophy and operational capability.

Traditional warehouses were built for human workers. Aisles are sized for people pushing carts, shelving heights accommodate human reach, and processes are designed around human capabilities and limitations. When robots are introduced to these environments, they must adapt to spaces not optimized for their operation.

A robot-native facility, by contrast, begins with the question: "How would we design this space if robots were the primary operators?" The result is dramatically different:

- Architectural Design: Rather than wide aisles and fixed shelving, robot-native facilities feature dense storage configurations that maximize space utilization. Ceiling heights, floor materials, and even lighting are optimized for robotic rather than human requirements.

- Algorithmic Workflows: Instead of fitting robots into human-designed processes, robot-native centers build workflows that capitalize on robotic strengths—continuous operation, precise movement, and data-driven decision making.

- Systems Integration: The warehouse management system doesn't merely communicate with robots; it orchestrates a comprehensive ecosystem where hardware and software function as a unified whole.

- Adaptable Infrastructure: Physical infrastructure is designed to evolve alongside robotic capabilities, allowing for seamless upgrades and expansions without operational disruption.

What truly sets robot-native fulfillment apart is that robots aren't viewed as tools to assist human workers but as the primary operational entities. Human roles shift toward supervision, exception handling, and strategic oversight rather than routine tasks.

This fundamental redesign allows robot-native centers to achieve performance levels impossible in retrofitted facilities. When warehouse robots operate in environments specifically engineered for their capabilities, their efficiency increases exponentially.

The Core Benefits of Robot-Native Fulfillment Centers

The advantages of a robot-native approach extend far beyond the incremental improvements seen in traditionally automated facilities. These benefits are structural and compounding, creating a fundamentally superior operational model.

Unmatched Operational Efficiency

In conventional warehouses—even those with automation—movement remains constrained by human-centric layouts. OPLOG’s robot-native fulfillment centers, powered by TARQAN, remove these limitations. By combining algorithmically optimized inventory placement with AGV-based workflows, OPLOG redefines operational efficiency. Academic studies have shown that integrating AGVs into order picking processes can reduce task time by up to 33.57% compared to manual methods—underscoring the transformative potential of OPLOG’s approach.

This efficiency isn't just about speed—it's about intelligence. When a warehouse robot operates in a truly native environment, it can make real-time decisions based on order patterns, inventory placement, and facility conditions. The result is a self-optimizing system that continuously improves its own performance.

Precision At Scale

Robot-native centers achieve accuracy rates that manual operations simply cannot match. Traditional fulfillment typically sees error rates around 1-3%, but robot-native fulfillment can reduce this to 0.1% or lower.

This precision scales linearly—unlike human operations where accuracy tends to decrease as volume increases. During peak periods, when error rates in conventional warehouses typically spike, robot-native facilities maintain consistent performance levels.

Density and Space Utilization

Perhaps the most visually striking difference in robot-native facilities is their storage density. Without the need for human-accessible aisles or limitations on reach, these fulfillment centers can make far more efficient use of space, stacking and organizing inventory in ways that would be impossible in traditionally designed warehouses.

This density creates a virtuous cycle: more inventory in less space means shorter travel distances, which further increases efficiency. The compact design also reduces real estate requirements, allowing fulfillment operations to exist closer to urban centers—critical for same-day delivery capabilities.

Adaptive Capacity

Traditional warehouses face significant challenges during peak periods. Adding temporary staff requires training and creates operational complexity. Robot-native centers, by contrast, can scale capacity seamlessly.

OPLOG's robotic logistics framework allows for dynamic resource allocation, automatically redirecting robotic capacity to areas experiencing higher demand. This built-in flexibility means handling volume surges of 400% or more with minimal disruption—a critical capability in today's volatile market.

Environmental and Economic Sustainability

The robot-native approach offers notable sustainability advantages. By enabling more efficient movement patterns and reducing the need for climate control and lighting, these facilities consume significantly less energy per order than traditional human-centric warehouses.

From an economic perspective, the reduced footprint and higher throughput create a compelling ROI. While initial investment may be higher than traditional automation retrofits, the total cost per order processed is substantially lower over time, with many operations seeing breakeven in less than two years.

TARQAN: OPLOG's Robot-Native Approach to Fulfillment

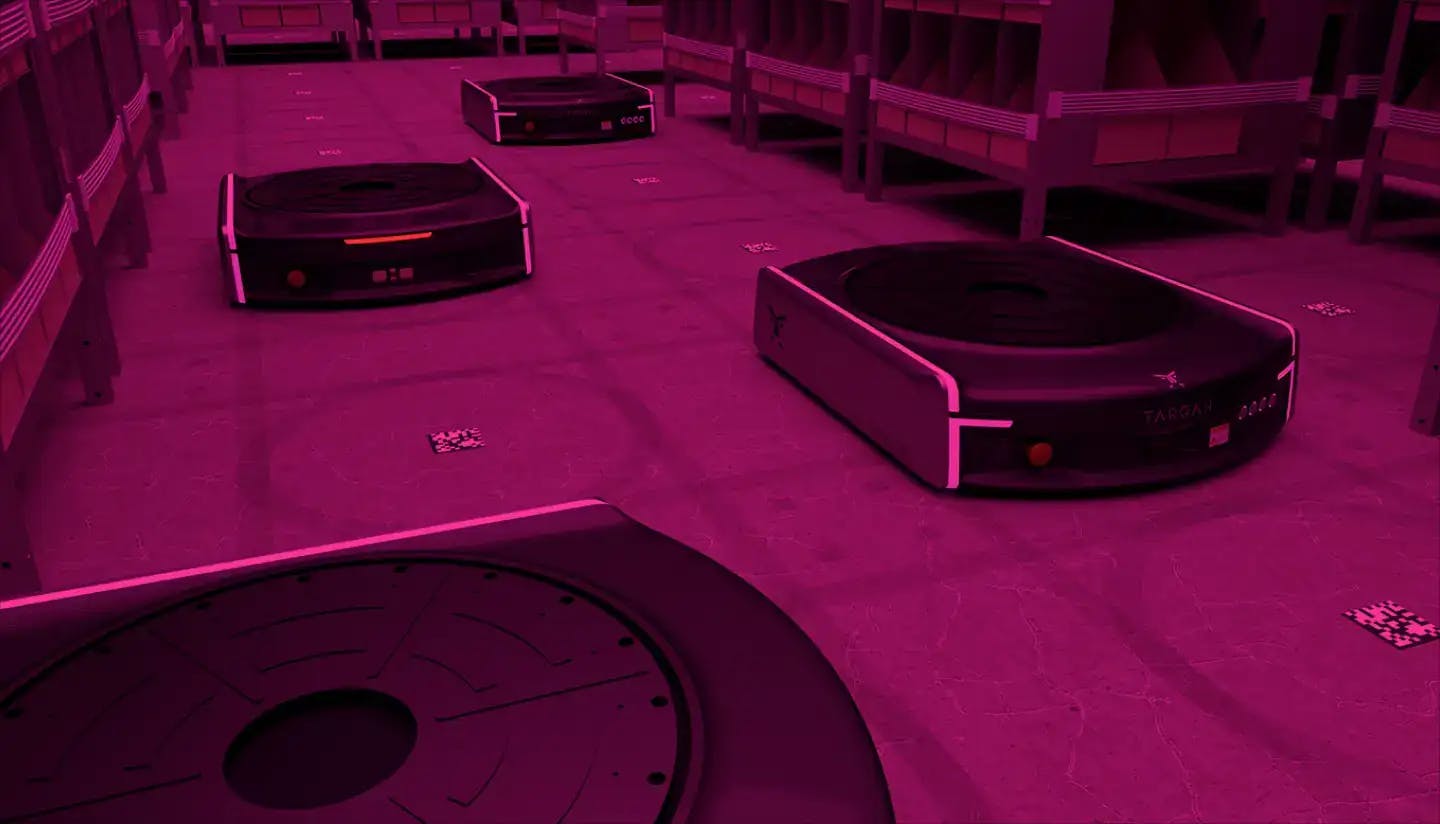

OPLOG's proprietary TARQAN represents the culmination of robot-native design principles. Rather than adopting off-the-shelf automation solutions, TARQAN was developed specifically to create a seamless robotic ecosystem where every component—physical and digital—works in harmony.

System Architecture

TARQAN is the latest generation warehouse robot developed in-house by OPLOG to meet the demands of next-generation fulfillment operations. As an autonomous guided vehicle (AGV), TARQAN plays a key role in OPLOG’s tightly integrated warehouse ecosystem—working seamlessly alongside conveyor systems, sorting mechanisms, and other automation technologies.

Unlike conventional modular automation setups—where disparate systems often create delays at handoff points—OPLOG’s integrated approach ensures a continuous, frictionless flow of goods from inbound to outbound. TARQAN contributes to this harmony by executing tasks with precision and flexibility, enhancing both speed and efficiency across the entire fulfillment process.

Adaptive Intelligence

What truly sets TARQAN apart is how it works in harmony with OPLOG’s in-house warehouse management system (OPLOG WMS, "Maestro"). Together, they create a continuously improving fulfillment environment. While TARQAN handles physical movement with precision and flexibility, OPLOG WMS drives intelligence behind the scenes.

Using predictive algorithms, OPLOG WMS can anticipate order patterns and proactively reposition inventory to reduce future travel distances. This coordinated approach transforms warehouse operations from reactive to proactive—enabling a system that not only maintains performance, but actively optimizes it over time.

Human-Robot Collaboration

Despite its robot-native design, TARQAN doesn't eliminate human workers—it transforms their roles. By handling routine tasks through robotic systems, TARQAN allows human associates to focus on exception handling, quality control, and customer-specific customization.

This collaborative approach leverages the strengths of both robots (consistency, endurance, precision) and humans (adaptability, judgment, dexterity). The result is a hybrid operation that exceeds the capabilities of either robots or humans working independently.

Real-World Performance

In practice, TARQAN has demonstrated impressive performance metrics:

- Order accuracy exceeding 99.9%

- Throughput increases of 400% compared to traditional operations

- Labor efficiency improvements of 200-250%

- Ability to process orders within minutes of receipt

These results aren't theoretical—they represent actual performance in high-volume production environments handling diverse product categories and order profiles.

Future Outlook: The Evolution of Robot-Native Logistics

The robot-native fulfillment center of today represents just the beginning of a fundamental transformation in logistics. As technologies evolve and operational models mature, we can expect several key developments:

Increased Intelligence and Autonomy

Current robot-native systems still require significant human oversight. The next generation will feature greater autonomy, with systems capable of making complex decisions without human intervention. This will include automated exception handling, predictive maintenance, and self-organizing inventory.

Seamless Omnichannel Integration

Future robot-native fulfillment centers will blur the lines between different channels, creating unified inventory pools that can serve B2B, DTC, and retail replenishment simultaneously. This convergence will eliminate the operational silos that currently exist in many organizations.

Ecosystem-Level Optimization

While today's systems optimize within the four walls of the fulfillment center, future iterations will extend optimization across the entire supply chain. This will include coordinated planning with suppliers, transportation providers, and retail partners to create end-to-end efficiency.

Sustainability as a Core Feature

Environmental considerations will become increasingly central to robot-native design, with systems optimized not just for operational efficiency but also for minimal environmental impact. This will include energy-efficient movement patterns, sustainable packaging selection, and carbon-optimized fulfillment decisions.

Organizations that embrace the robot-native approach today position themselves to evolve alongside these developments, creating a foundation for continued competitive advantage as the logistics landscape transforms.

Frequently Asked Questions

Summary

The rise of robot-native fulfillment centers represents not just an evolution but a revolution in logistics operations. By designing facilities and systems specifically for robotic operation rather than retrofitting automation into human-centric environments, organizations can achieve unprecedented levels of efficiency, accuracy, and scalability.

OPLOG's TARQAN exemplifies this approach, creating an integrated robotic logistics ecosystem where every element works in harmony. The results—dramatically improved performance, enhanced sustainability, and the ability to meet increasingly demanding consumer expectations—demonstrate the transformative potential of robot-native fulfillment.

As e-commerce continues to evolve and consumer expectations rise further, the robot-native model will become not just a competitive advantage but a necessity for organizations seeking to thrive in the digital commerce landscape. Those who embrace this approach today position themselves for success not just in current market conditions but in the rapidly approaching future of logistics.