Why Legacy Fulfillment Models Will Fail in the AI and Automation Era

The numbers tell a stark story: Warehouse automation markets are exploding while only 25% of warehouses worldwide have adopted automation technologies—with approximately 75% still operating manually without any automation support.

This leaves a massive gap between where the industry is and where it needs to be. This isn't just about keeping up with trends. It's about survival in an environment where 80% of consumers expect same-day delivery, 86% define fast delivery as 2 days or less, and where global parcel volumes are projected to reach 220-262 billion packages by 2026.

Legacy fulfillment models, built for static operations and manual processes, simply cannot scale to meet these demands. Third-party logistics providers widely face challenges with outdated technology systems and digital transformation, while 70% of online shoppers consider delivery speed a key factor in their purchasing decisions. These figures clearly demonstrate that traditional logistics models are no longer sustainable in today's rapidly evolving marketplace.

The Fundamental Flaws of Legacy Fulfillment

Rigid Infrastructure Built for Yesterday's Challenges

Traditional 3PL operations were designed during an era when e-commerce was supplementary to brick-and-mortar retail. These systems assumed:

- Predictable order patterns with bulk shipments to retail locations

- Standard operating hours with human-paced workflows

- Limited SKU complexity and straightforward inventory management

- Forgiving delivery expectations measured in weeks, not hours

Today's reality couldn't be more different. Modern brands face:

- Dynamic inventory demands that fluctuate by the hour

- Multi-channel complexity spanning B2B, B2C, and D2C simultaneously

- Real-time customer expectations for tracking and delivery updates

Seasonal volume spikes that can increase throughput requirements dramatically - with some operations seeing order volumes surge from 10,000 to 90,000 daily during peak

The Technology Debt Crisis

Research reveals that 60% of U.S. businesses still rely on Excel spreadsheets for critical operations, with 94% of these spreadsheets containing critical errors. In fulfillment operations, this translates to:

Fragmented System Architecture: Legacy 3PLs typically operate with disconnected Warehouse Management Systems (WMS), Transportation Management Systems (TMS), and Order Management Systems (OMS). These siloed systems create:

- Data inconsistencies across platforms

- Manual reconciliation requirements

- Delayed visibility into inventory and orders

- Inability to optimize across the entire fulfillment network

Manual Process Dependencies: Traditional fulfillment relies heavily on human intervention for:

- Order routing and prioritization

- Inventory allocation decisions

- Exception handling and problem resolution

- Quality control and verification

While human expertise remains valuable, manual dependencies create bottlenecks that prevent scalable growth and introduce error rates that modern customers won't tolerate.

The Cost of Operational Inflexibility

Legacy fulfillment models typically require:

Long-term commitments with rigid pricing structures that don't accommodate seasonal fluctuations or business growth patterns. Brands often find themselves locked into contracts that become constraints rather than solutions.

Fixed infrastructure that can't adapt to changing business needs. Traditional warehouses designed for bulk storage struggle to handle the piece-picking, rapid sortation, and multi-channel distribution requirements of modern e-commerce.

Limited scalability options that force businesses to choose between expensive expansions or capacity constraints during peak periods.

The New Fulfillment Reality: What Modern Commerce Demands

Speed at Enterprise Scale

Amazon has fundamentally reset customer expectations by shipping 1.6 million packages daily with their network of 750,000 operational robots. This robot-native approach has delivered:

- 20% reduction in fulfillment costs

- 40% increase in order processing capacity

- 98% picking accuracy rates

But Amazon's infrastructure represents just the beginning. Modern fulfillment operations require:

Real-time Processing: Advanced automation enables order processing to increase from 1-2 items per minute to 25 items per minute through robotics supporting same-day delivery promises. This demands automated systems that can:

- Instantly evaluate inventory across multiple locations

- Dynamically route orders to optimal fulfillment points

- Coordinate picking, packing, and shipping without manual intervention

Predictive Optimization: Advanced AI systems analyze demand patterns, inventory levels, and capacity constraints to:

- Pre-position inventory based on demand forecasting

- Optimize labor allocation across shifts and seasonal patterns

- Identify and resolve potential bottlenecks before they impact operations

Dynamic Inventory Intelligence

- Modern fulfillment requires AI-driven inventory management that goes far beyond traditional stock level monitoring. Industry leaders are achieving:

- 30% reduction in forecast error rates through machine learning algorithms

- 15% decrease in safety stock requirements via predictive analytics

- Enhanced responsiveness to demand pattern changes through real-time data integration, where automation systems such as real-time inventory tracking and automated replenishment allow businesses to quickly respond to demand changes and maintain optimal stock levels

This level of sophistication demands infrastructure that can:

- Process multiple data streams simultaneously

- Adapt inventory policies in real-time

- Coordinate replenishment across supply networks

- Integrate with supplier systems for just-in-time restocking

Seamless Brand Experience Integration

Traditional 3PLs often operate as service providers with limited integration into brand experiences. Modern fulfillment requires unified customer experience orchestration that includes:

Real-time Visibility: Customers expect granular tracking information that legacy systems simply cannot provide. Modern infrastructure offers:

- Live location tracking with estimated delivery windows

- Proactive notifications about delays or changes

- Detailed order status updates across all touchpoints

Flexible Delivery Options: Brands need the ability to offer:

- Multiple delivery speed options with accurate pricing

- Alternative delivery locations and time windows

- Easy modification and cancellation capabilities

- Seamless returns processing with instant refunds

The Technology Infrastructure Gap

Why Legacy Systems Cannot Adapt

The challenge facing traditional 3PLs isn't just about adding new technology—it's about fundamental architectural limitations that prevent effective modernization:

Monolithic System Design: Legacy systems were built with integrated, inflexible architectures that make it extremely difficult to:

- Integrate new technologies without disrupting existing operations

- Scale individual components based on demand

- Update systems without significant downtime

- Customize workflows for different client requirements

Data Integration Barriers: Traditional systems often trap data in proprietary formats that make it difficult to:

- Share information across platforms in real-time

- Apply modern analytics and AI technologies

- Provide customers with unified visibility

- Optimize operations based on comprehensive data insights

The Robot-Native Advantage

Modern fulfillment infrastructure is being built from the ground up with robot-native architectures that assume automation as the default rather than an add-on. This approach enables:

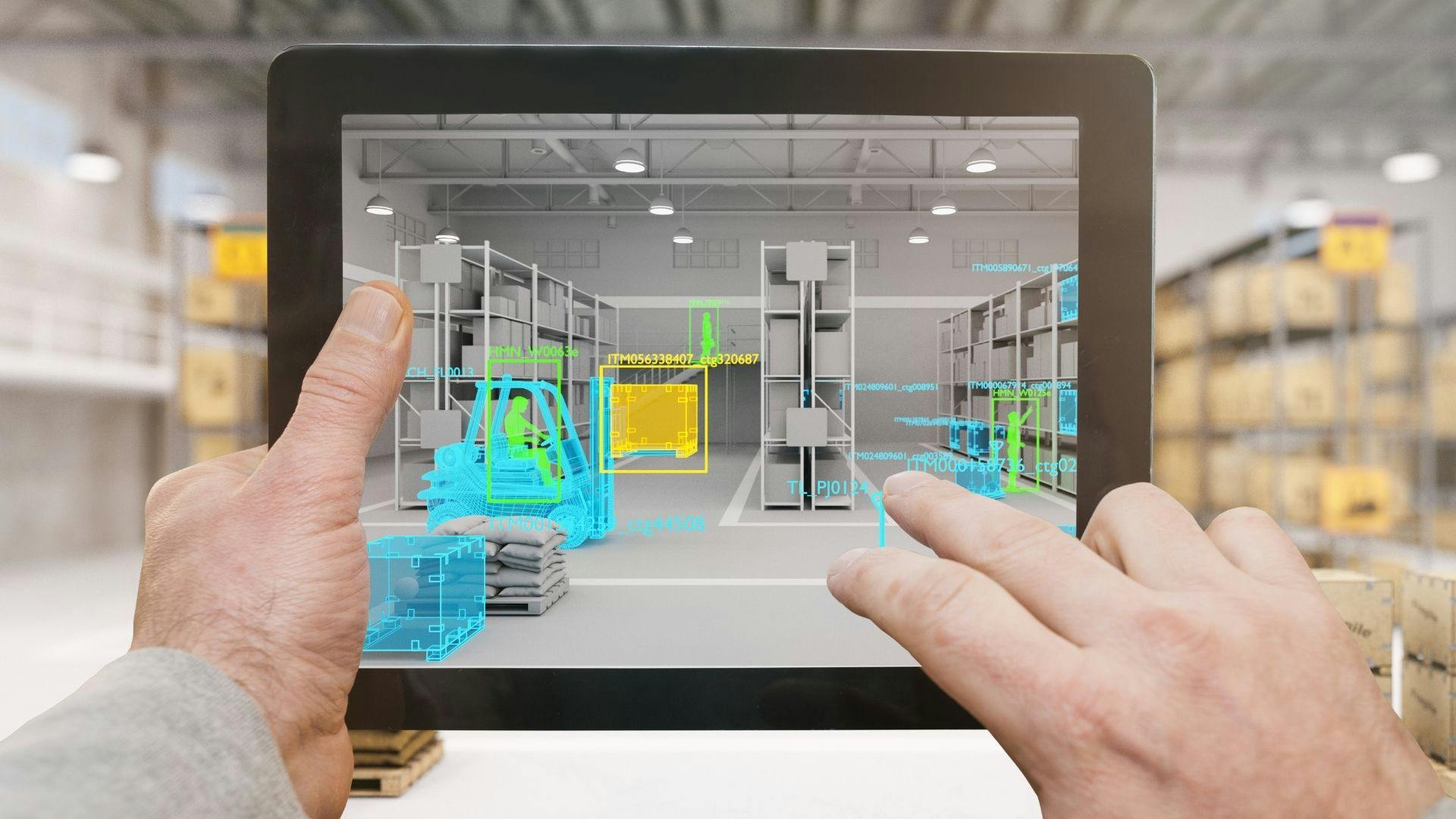

Unified Control Systems: Modern platforms integrate robotics, conveyor systems, sortation equipment, and software under unified control that can:

- Coordinate complex multi-robot operations

- Optimize workflows across automated and manual processes

- Adapt to changing operational requirements in real-time

- Scale capacity by adding robotic units rather than expanding facilities

AI-Driven Decision Making: Robot-native systems leverage artificial intelligence for:

- Route optimization that reduces fulfillment time by up to 30%

- Predictive maintenance that prevents equipment downtime

- Dynamic labor allocation based on real-time demand patterns

- Quality control automation using computer vision systems

Cloud-Native Scalability

Modern fulfillment operations require cloud-native infrastructure that can:

Scale on Demand: Handle volume fluctuations without requiring physical infrastructure changes Integrate Seamlessly: Connect with e-commerce platforms, ERPs, and carrier systems through standardized APIs Update Continuously: Deploy new features and improvements without operational disruption Provide Global Visibility: Offer real-time insights across distributed fulfillment networks

The Future-Ready Alternative: Robot-Native Fulfillment

Designing for Dynamic Operations

The most successful modern fulfillment operations are being built with robot-native infrastructures that assume automation as the foundation rather than an enhancement. This approach delivers several critical advantages:

Adaptive Capacity: Robot-native systems can scale fulfillment capacity without proportional increases in labor costs or facility footprint. Advanced systems demonstrate:

- 3x higher throughput per square foot compared to traditional operations

- 99.7% uptime with automated maintenance and monitoring

- Sub-second response times to inventory and order changes

Operational Resilience: Automated systems provide continuity during disruptions that would halt traditional operations:

- Consistent performance during labor shortages

- 24/7 operations capability without shift management complexity

- Reduced dependency on specialized human expertise for routine operations

AI-Driven Predictive Operations

Modern fulfillment infrastructure leverages artificial intelligence not just for automation, but for predictive optimization that anticipates needs before they become constraints:

Demand Forecasting: Advanced AI systems analyze multiple data streams to predict:

- Seasonal demand patterns with up to 50% error reduction compared to traditional methods, enabling planning weeks to months in advance

- Product lifecycle stages that affect inventory requirements

- Regional demand patterns that inform inventory positioning

Capacity Planning: Predictive analytics enable:

- Dynamic staffing adjustments based on forecasted volumes

- Proactive equipment maintenance that prevents unexpected downtime

- Inventory pre-positioning that reduces fulfillment times

Network Optimization: AI-driven systems continuously optimize:

- Order routing across multiple fulfillment locations

- Transportation mode selection based on cost and speed requirements

- Inventory allocation that minimizes total fulfillment costs

Pay-as-You-Scale Economic Models

Traditional fulfillment requires significant upfront commitments and rigid pricing structures that often become constraints as businesses grow. Modern fulfillment platforms offer pay-as-you-scale models that:

Align Costs with Growth: Brands pay for actual capacity used rather than committed minimums Eliminate Capital Requirements: No upfront investment in automation equipment or technology Provide Pricing Transparency: Real-time cost visibility for every order and operation Support Seasonal Flexibility: Capacity scales automatically with demand fluctuations

OPLOG: The Robot-Native Fulfillment Platform

OPLOG represents the next generation of fulfillment infrastructure—designed from the ground up for the AI and automation era. Unlike traditional 3PLs that attempt to retrofit legacy systems with modern technology, OPLOG's robot-native platform delivers:

Unified Technology Architecture

OPLOG's platform integrates robotics, AI, and cloud-native software into a single, coordinated system that eliminates the silos and inefficiencies of traditional fulfillment:

- Real-time inventory visibility across all channels and locations

- Automated order routing that optimizes for speed, cost, and customer preferences

- Predictive analytics that anticipate demand patterns and capacity requirements

- Seamless integration with e-commerce platforms, ERPs, and customer systems

Dynamic Scaling Capability

The OPLOG platform automatically adjusts to demand fluctuations without requiring:

- Long-term capacity commitments

- Manual staffing adjustments

- Technology integration delays

- Facility expansion projects

Brands can scale from startup volumes to enterprise capacity within the same platform, paying only for actual usage while maintaining consistent service levels.

Customer-Centric Design

Unlike traditional 3PLs that operate as service providers, OPLOG functions as an extension of brand operations:

Transparent Operations: Real-time visibility into every aspect of fulfillment operations Flexible Configuration: Customizable workflows that match brand requirements and customer expectations

Seamless Integration: Direct connection with customer-facing systems for unified experiences Proactive Communication: Automated updates and notifications that keep customers informed

Advanced Analytics and Optimization

OPLOG's AI-driven platform continuously analyzes operations to identify optimization opportunities:

- Cost optimization that reduces fulfillment expenses while improving service levels

- Performance analytics that identify trends and improvement opportunities

- Predictive insights that enable proactive decision-making

- Benchmarking data that shows performance relative to industry standards

Making the Transition to Future-Ready Fulfillment

Assessing Your Current State

Brands considering the transition from legacy fulfillment should evaluate their current operations across several key dimensions:

Technology Integration: How well do your current systems provide real-time visibility and seamless data flow? Scalability Constraints: What limitations prevent your current fulfillment from scaling with business growth? Cost Structure: How predictable and transparent are your current fulfillment costs? Customer Experience: How does your fulfillment performance impact brand perception and customer satisfaction?

Implementation Strategy

Successful transitions to modern fulfillment typically follow a phased approach that minimizes disruption while maximizing benefits:

Phase 1: Assessment and Planning

- Comprehensive analysis of current fulfillment performance

- Identification of key improvement opportunities

- Definition of success metrics and timelines

Phase 2: Pilot Implementation

- Migration of specific product lines or channels

- Performance monitoring and optimization

- Staff training and process refinement

Phase 3: Full Integration

- Complete migration to robot-native platform

- Advanced feature activation and customization

- Long-term optimization and continuous improvement

Measuring Success

Modern fulfillment platforms provide unprecedented visibility into performance metrics that matter:

Operational Efficiency:

- Order cycle time from placement to shipment

- Fulfillment accuracy and error rates

- Inventory turnover and carrying costs

Customer Experience:

- Delivery performance against commitments

- Customer satisfaction scores and feedback

- Return processing speed and accuracy

Business Impact:

- Fulfillment cost per order

- Capacity utilization and scalability headroom

- Revenue impact from improved service levels

The Imperative for Change

The transformation of fulfillment operations isn't optional—it's an operational imperative driven by irreversible market forces:

Customer Expectations: Modern consumers have been conditioned by leaders like Amazon to expect near-instant gratification with complete transparency. Brands that cannot meet these expectations risk customer defection to competitors who can.

Competitive Pressure: Early adopters of robot-native fulfillment are achieving 20-40% cost advantages while delivering superior customer experiences. This creates a competitive disadvantage that compounds over time.

Operational Complexity: The complexity of modern commerce—with multiple channels, dynamic inventory, and real-time customer expectations—simply cannot be managed effectively with manual processes and legacy systems.

Technology Acceleration: The pace of automation and AI advancement means that the gap between legacy and modern fulfillment will only widen. Brands that delay transformation risk being left behind permanently.

Conclusion: Embracing the Robot-Native Future

Legacy fulfillment models served their purpose in an era of predictable operations and forgiving customer expectations. But that era has ended. Today's dynamic, customer-centric commerce environment demands robot-native infrastructure that can scale instantly, optimize continuously, and deliver seamlessly.

The question isn't whether traditional fulfillment models will fail—it's how quickly brands will embrace the technologies and platforms that define the future of commerce operations. Companies like OPLOG are providing the blueprint for this transformation, offering robot-native platforms that eliminate the constraints of legacy fulfillment while enabling unprecedented levels of performance and scalability.

For brands ready to leave behind the limitations of traditional 3PLs, the path forward is clear: embrace robot-native fulfillment platforms that are designed for the AI and automation era. The competitive advantages of modern fulfillment infrastructure are too significant to ignore, and the risks of remaining with legacy systems are too great to accept.

The future of fulfillment is here. The only question is whether your brand will lead the transformation or be left behind by it.

Ready to explore robot-native fulfillment for your brand? OPLOG's platform is designed to eliminate the constraints of legacy fulfillment while delivering the speed, scalability, and transparency that modern commerce demands. Contact our team to learn how robot-native infrastructure can transform your fulfillment operations and accelerate your business growth.