In today's rapidly evolving e-commerce landscape, businesses face unprecedented challenges in meeting consumer demands for speed, accuracy, and efficiency. With global e-commerce volumes soaring to over $5 trillion and consumer expectations for rapid delivery becoming the norm rather than the exception, traditional fulfillment methods are increasingly falling short. The solution? Enter robotic fulfillment – a revolutionary approach that's transforming how businesses handle order processing and warehouse management.

The Evolution of Fulfillment Technology

The journey from manual warehouse operations to today's sophisticated robotic systems represents one of the most significant technological leaps in logistics. What began with simple conveyor belts and basic automation has evolved into an ecosystem of intelligent machines working in harmony to revolutionize the entire fulfillment process.

Traditional fulfillment operations often struggle with multiple challenges:

- Labor shortages and rising costs

- Inefficient space utilization

- Quality control challenges in manual fulfillment

- Limited scalability during peak seasons

- Slow processing times

Robot-native fulfillment systems address these challenges head-on by integrating cutting-edge technologies that work alongside human operators, creating an environment where both can excel in their respective strengths.

What is Robot-Native Fulfillment?

Robot-native fulfillment refers to warehouse and distribution systems fundamentally designed around robotic capabilities, rather than merely adding robots to existing warehouse configurations. These purpose-built environments optimize the interaction between humans and machines, creating synchronized workflows that maximize efficiency.

At the core of this revolution is the integration of several key technologies:

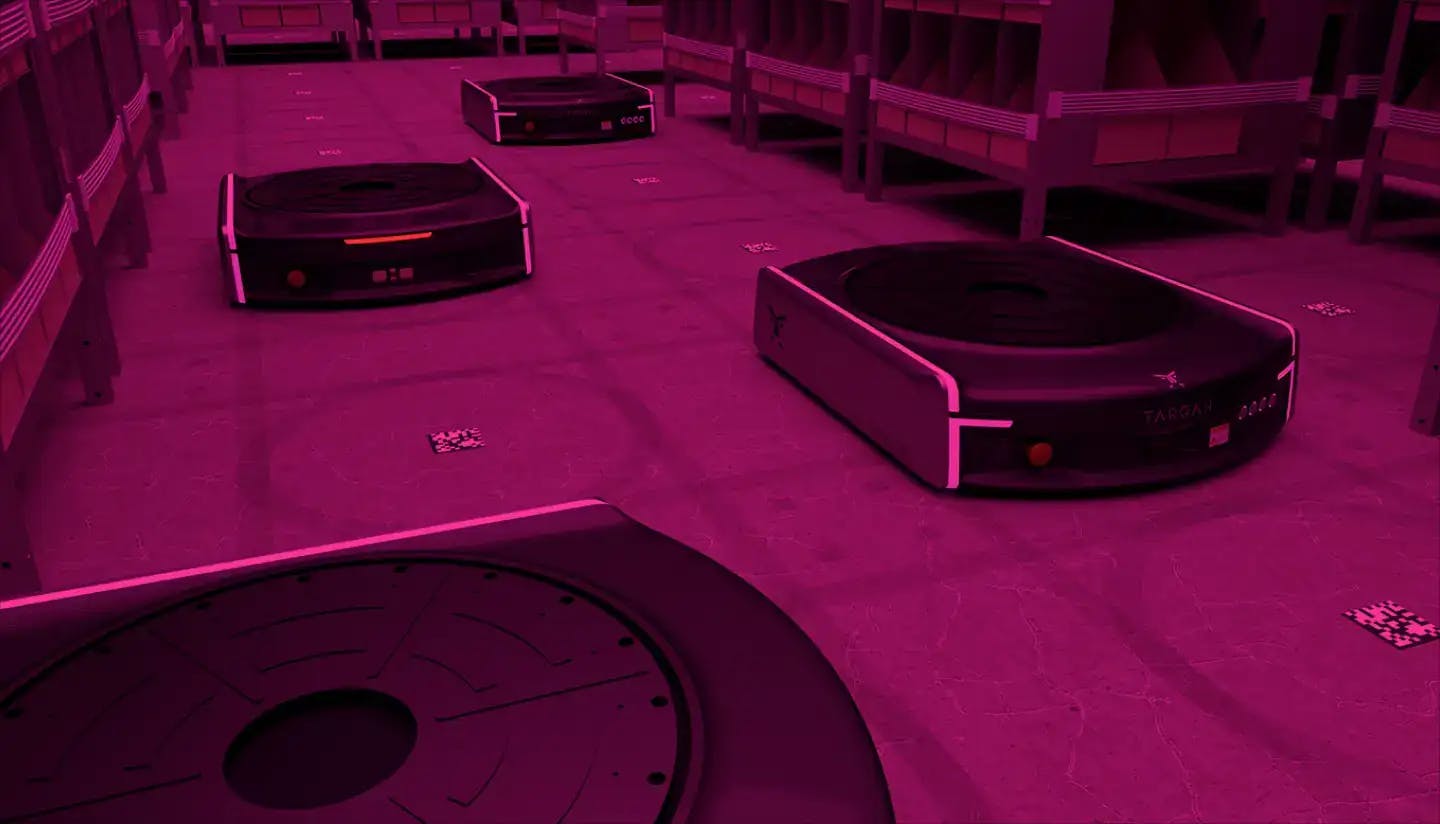

1. Autonomous Mobile Robots (AMRs)

Unlike traditional Automated Guided Vehicles (AGVs) that follow fixed paths, Autonomous Mobile Robots (AMRs) use advanced sensors, cameras, and AI to navigate dynamically through warehouse environments. They can:

- Make real-time decisions to avoid obstacles

- Adapt routes based on warehouse conditions

- Work collaboratively with humans

- Transport inventory without fixed infrastructure requirements

2. Goods-to-Person Systems

Rather than having workers traverse vast warehouse spaces searching for items, goods-to-person systems bring products directly to packing stations. TARQAN, OPLOG's advanced fulfillment robot, exemplifies this approach.

TARQAN can:

- Transport shelves containing up to one ton of merchandise

- Increase picking efficiency by 300% (400-500 products per hour vs. 120-150 by human workers)

- Reduce labor costs by optimizing human resource allocation

- Achieve 99.99% picking accuracy3. Robotic Arms and Picking Systems

- Sophisticated robotic arms equipped with computer vision can identify, grasp, and manipulate a wide variety of products with remarkable precision. These systems:

- Handle diverse items from fragile electronics to soft textiles

- Scan barcodes and verify products in real-time

- Pack items efficiently with optimal packaging selection

- Operate continuously 24/7 without fatigue

- Adapt grip strength based on item characteristics

4. AI-Powered Warehouse Management Systems

The intelligence behind robotic fulfillment comes from advanced software systems that orchestrate the entire operation. These systems:

- Dynamically optimize inventory placement using predictive analytics

- Coordinate robot movements to minimize congestion and maximize throughput

- Predict maintenance needs before failures occur, ensuring uptime

- Provide real-time visibility and actionable insights into operations

The TARQAN Advantage: Fulfillment Robots Made by Fulfillment Experts

What sets truly innovative solutions like TARQAN apart is their origin – developed by companies with deep expertise in fulfillment operations. OPLOG's unique approach stems from over a decade of real-world experience managing complex fulfillment operations for major brands like SONY, Rossmann, and Tupperware.

TARQAN represents a significant leap forward in robotic fulfillment technology:

- Purpose-Built Design: Created specifically to address the everyday challenges experienced firsthand in fulfillment operations

- Industry-Leading Dimensions: Its optimal size helps maximize warehouse storage space

- Sophisticated Engineering: Features a unique carbon fiber shell for durability and longevity. Carbon fiber construction ensures durability while minimizing weight

- Intelligent Fleet Management: Powered by an advanced system that maps optimal routes for seamless operations

What truly distinguishes TARQAN is its development by fulfillment professionals who intimately understand the industry's pain points. This practical expertise is embedded into every aspect of its design, creating a solution that addresses real-world challenges rather than theoretical ones.Key Benefits of Robotic Fulfillment

1. Dramatic Efficiency Improvements

The numbers speak for themselves:

- While human workers typically collect 120-150 products per hour, robotic systems like TARQAN can process 400-500 products hourly

- This 300% increase in efficiency translates directly to faster order processing

- Reduced walking time for workers means less fatigue and more focus on value-added tasks

2. Enhanced Accuracy and Quality Control

Human errors in picking and packing can be costly:

- Incorrect orders lead to returns, which cost businesses approximately 66% of the original product's price

- Customer dissatisfaction from errors damages brand reputation

- Robotic systems achieve up to 99.99% picking accuracy, virtually eliminating these issues

3. Scalability for Peak Seasons

E-commerce businesses face significant challenges during peak seasons:

- Traditional methods require hiring and training temporary staff

- Quality and efficiency often suffer during these critical periods

- Robotic systems can scale operations instantly without compromising performance

4. Optimized Space Utilization

Modern warehouse space comes at a premium:

- Robotic systems navigate more efficiently than humans, requiring narrower aisles

- Vertical space can be better utilized with robots capable of accessing higher shelving

- This optimization can reduce facility footprint while increasing storage capacity

5. Reduced Operational Costs

While the initial investment in robotic systems is significant, the long-term financial benefits are compelling:

- Labor costs decrease as fewer workers are needed for the same output

- Error-related expenses diminish substantially

- Energy efficiency improves with optimized operations

- Equipment maintenance becomes predictive rather than reactive

6. Better Working Conditions for Employees

Rather than replacing humans, robotic fulfillment transforms the nature of warehouse work:

- Physical strain decreases as robots handle heavy lifting

- Repetitive tasks are automated, allowing workers to focus on more engaging responsibilities

- New roles emerge in robot maintenance, supervision, and system optimization

- Employee satisfaction improves with safer, more varied work

The Future of Robotic Fulfillment

As we look ahead to 2025 and beyond, several trends will shape the evolution of robotic fulfillment:

1. AI and Machine Learning Advancements

Next-generation robots will feature increasingly sophisticated intelligence:

- Self-optimizing algorithms that continuously improve performance

- Enhanced adaptability to changing product assortments

- Predictive capabilities for inventory management

- More natural human-robot collaboration

2. Expanded Capabilities

Future robotic systems will handle more complex tasks:

- Delicate item manipulation for fragile products

- Custom packaging based on order characteristics

- Quality inspection using computer vision

- Returns processing and assessment

3. Democratization of Access

While currently dominated by large enterprises, robotic fulfillment will become more accessible to mid-sized businesses through:

- Robotics-as-a-Service (RaaS) models reducing upfront costs

- Modular systems allowing gradual implementation

- Simplified integration with common e-commerce platforms

- Standardized interfaces and protocols

4. Sustainability Focus

Environmental considerations will play an increasingly important role:

- Energy-efficient robot designs

- Optimized routing to reduce power consumption

- Precise packaging reducing material waste

- Extended equipment lifecycles through predictive maintenanceHow OPLOG is Leading the Robotic Fulfillment Revolution

- OPLOG stands at the forefront of the robotic fulfillment revolution, leveraging cutting-edge technologies to enhance e-commerce operations with unparalleled speed, accuracy, and scalability.

- Our approach combines several key elements:

- TARQAN Robotic Fleet: Our proprietary robot-native fulfillment system increases picking efficiency by 300% while achieving 99.99% accuracy

- Integrated Software Ecosystem: OPLOG ONE seamlessly connects every touchpoint in the fulfillment journey

- Strategic Facility Locations: Positioned to optimize delivery speed to major markets

- Human-Robot Collaboration: Creating the perfect harmony between advanced automation and skilled human expertise

By integrating these advanced automation solutions, OPLOG empowers businesses to meet increasing consumer demands and navigate peak seasons with efficiency and precision that was previously unattainable.

Is Robotic Fulfillment Right for Your Business?

While the benefits of robotic fulfillment are compelling, the decision to implement depends on several factors:

Consider Robotic Fulfillment If:

- You experience significant seasonal fluctuations

- Labor costs or availability pose ongoing challenges

- Order accuracy issues impact customer satisfaction

- Growth is constrained by fulfillment capacity

- Speed of delivery is a competitive factor in your market

Start Your Robotic Fulfillment Journey

The transition to robotic fulfillment doesn't have to happen overnight. Consider these steps:

- Assessment: Evaluate your current fulfillment operations, identifying bottlenecks and opportunities

- Education: Learn about available technologies and how they apply to your specific needs

- Partnering: Consider working with fulfillment providers like OPLOG that already leverage robotic systems

- Piloting: Test robotic fulfillment on a portion of your inventory before full-scale implementation

- Scaling: Gradually expand robotic capabilities based on results and business growth

Conclusion

Robotic fulfillment represents the future of e-commerce operations, offering transformative benefits in efficiency, accuracy, and scalability. As consumer expectations continue to rise and competition intensifies, businesses that embrace these technologies gain a significant advantage in the marketplace.

OPLOG's TARQAN and integrated fulfillment solutions exemplify how purpose-built robotic systems, designed by fulfillment experts, can address the real-world challenges of modern e-commerce logistics. By combining cutting-edge technology with deep industry expertise, we're helping businesses of all sizes deliver exceptional customer experiences through faster, more reliable order fulfillment.

The robotic fulfillment revolution isn't just about replacing human labor with machines—it's about creating a more efficient, accurate, and scalable ecosystem where technology and human expertise combine to exceed customer expectations. As we move forward, those who embrace this revolution will find themselves well-positioned to thrive in the increasingly competitive world of e-commerce.