What are Consumables? A Guide to Turning "Invisible" Costs into Profit in E-Commerce

In the world of e-commerce, what happens between the moment a customer hits the "Buy" button and the moment the order appears at their doorstep determines the fate of your brand. Most business owners focus on product development, marketing, and sales. However, the silent heroes (or sometimes hidden enemies) of the operation are often overlooked: Consumables.

The answer to the frequently Googled questions "What are consumables?" and "What does consumable mean?"actually lies right at the center of your business's net profitability. Let's move this concept beyond just being a "stationery expense" and look at how you can transform it into a strategic growth tool with the OPLOG vision.

What are Consumables? (Basic Definition and Role in Logistics)

So, in its simplest form, what does consumable mean? Consumables are all the materials used during the production, packaging, or presentation of a product or service that are depleted as they are used and are generally not reusable.

However, for us logistics—or more accurately, fulfillment—and e-commerce professionals, a consumable is much more than just a "depleting resource." It is the single physical touchpoint you establish with your customer.

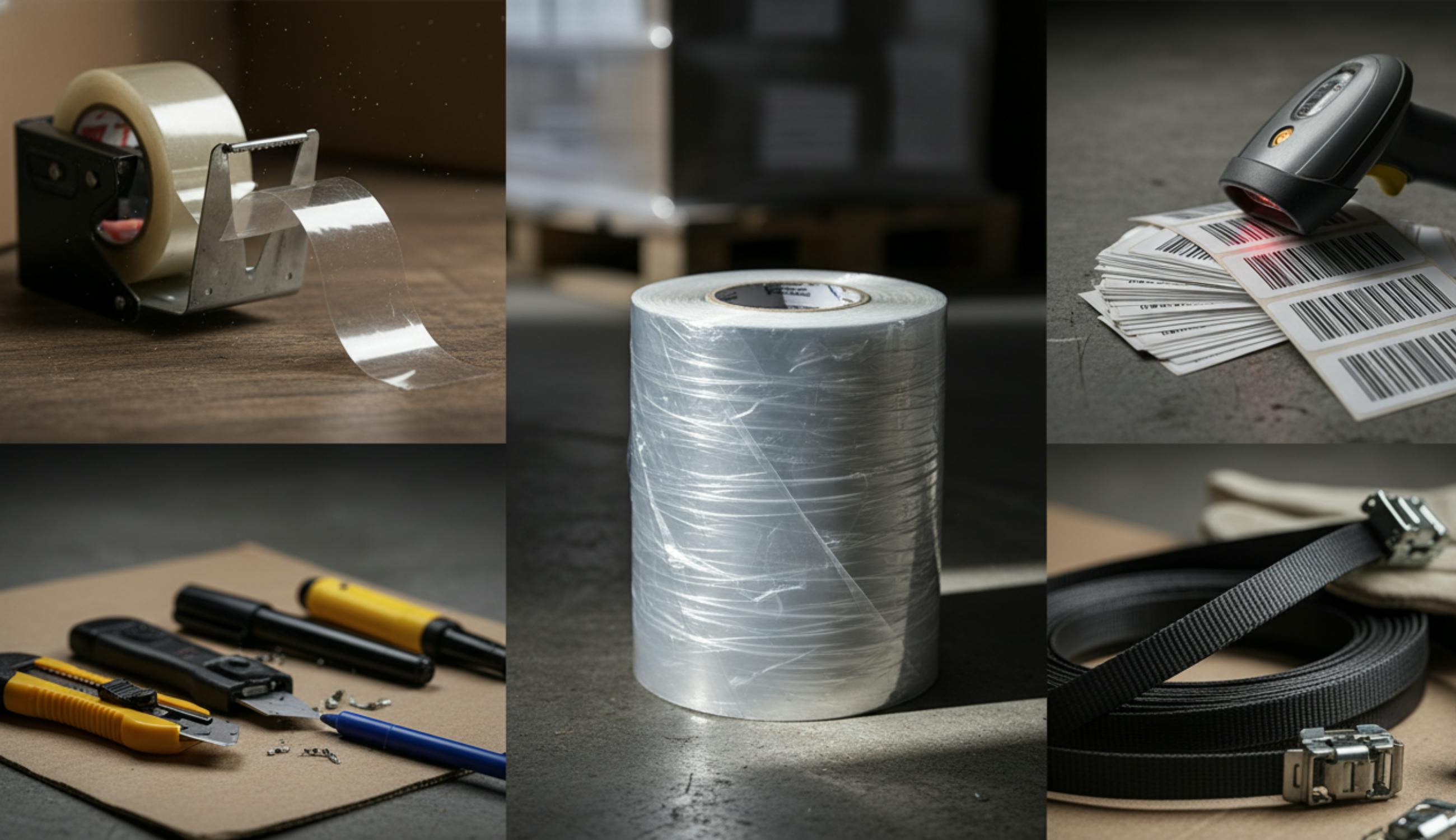

When we talk about consumables in e-commerce logistics (fulfillment), the following come to mind:

- Outer Packaging: Corrugated cardboard boxes, mailer bags (poly bags).

- Protective Materials: Bubble wrap, air pillows, kraft paper fillers, styrofoam.

- Sealing and Labeling: Packing tape, security tape, shipping barcode labels, waybill pouches (packing list envelopes).

For an e-commerce entrepreneur, this list represents "invisible money" leaving your wallet with every single order.

The Hidden Power of Consumables in E-Commerce: Why Is It Important?

Don't just say, "It's only a box, how important can it be?" In e-commerce, consumable management creates a direct impact in three critical areas:

1. Customer Experience (Unboxing Experience)

When your customer receives your product, the first thing they see isn't the product; it's the consumable. A crushed box, a package that lacks aesthetics and is over-taped, or a tiny product swimming inside a massive box can destroy your brand perception in seconds.

At OPLOG, we place great importance on "Unboxing Experience" capabilities, especially for D2C (Direct-to-Consumer) brands. Using the right consumables sends the message, "This brand values me," to your customer.

2. Cost Management and Profitability

Choosing the wrong size box, using more filler material than necessary, or packages popping open due to poor-quality tape... All of these are "waste" that eats away at your profitability.

Tracking these costs in traditional logistics processes is difficult. However, in OPLOG's technology-driven approach, unit economics are transparent, and your costs remain under control.

3. Sustainability

Consumers now pay attention to brands' environmental footprints. Unnecessary plastic use or tiny products arriving in huge boxes are shared on social media as "packaging waste." Proper consumable optimization protects both the planet and your brand image.

Sectoral Differences in Consumable Selection

Every product cannot be packed with the same consumable strategy. At OPLOG, with our expertise in different verticals, we know the importance of using materials suited to the nature of the product.

- Footwear: Shoe boxes are already protective, but they shouldn't get crushed during shipping. Here, the correct size outer box or durable mailer bags are critically important. Also, in this sector where returns are frequent, re-sealable packaging increases customer satisfaction.

- Beauty and Cosmetics: These products are generally small, fragile, and liquid. Here, "protective consumables" take the stage. Special fillers and leak-proofing measures that prevent the product from moving inside the box are vital.

- Apparel and Fashion: Here, keeping the volumetric weight (desi) low is important. Generally, light and durable mailer bags are preferred, while tissue paper and special boxes come into play in the luxury segment.

The OPLOG Difference: Managing Consumables with Technology

So, how will you manage hundreds of types of consumables, thousands of orders, and constantly changing costs? This is where OPLOG's technology-driven fulfillment approach comes into play. We don't just put your product in a box; we optimize your operation.

1. Preventing Waste with Robotic Precision (TARQAN)

Our proprietary TARQAN robotic technology used in our warehouses operates with a 99.9%+ accuracy rate during the order picking process. This precision continues into the packing stage. By matching the right consumable to the right product, unnecessary material usage is prevented. Materials going to waste due to human error and "wrong packaging" become a thing of the past.

2. Get Rid of Stock Burden with the Pay-As-You-Go (PAYG) Model

In traditional logistics or your own warehouse, you have to buy consumables in bulk and stock them. This both disrupts your cash flow and occupies your warehouse space. Thanks to OPLOG's "True PAYG" (True Pay-As-You-Go) model, you only face costs for the orders that actually happen.

You don't have to buy thousands of rolls of tape or boxes in advance. By leveraging OPLOG's economies of scale, you access consumables at much more affordable costs. Your fixed expenses turn into variable expenses.

3. Scalability and Flexibility

When your orders increase 10-fold during campaign periods (Black Friday, New Year's), running out of consumable stock can halt your operation. OPLOG's flexible infrastructure responds instantly to demand fluctuations. For growth-focused brands, this means focusing on sales without the worry of "running out of boxes".

Consumable Strategy in 5 Steps for Your Business

If you haven't yet entrusted your operation to a professional partner like OPLOG, you should follow these steps in consumable management:

- Conduct Product Analysis: Categorize the dimensions and fragility of your products. The "one box fits all" approach inflates your shipping costs (volumetric weight).

- Calculate Volumetric Weight (Desi): Remember that you also pay shipping fees for the empty space in the box you use. Choosing packaging closest to the product size provides shipping savings greater than the cost of the consumable itself.

- Supplier Diversity: Relying on a single supplier for consumables is risky. However, maintaining quality standards is harder.

- Branding Balance: Branded boxes are great but costly. Perhaps a high-quality label or tape applied to a standard box can provide the same effect much more cheaply.

- Think Automation: In manual processes, tape and filler usage varies from person to person. Standardization (SOP) is a must.

Conclusion: Turn Logistics into a Growth Lever

The question "What are consumables?" may seem simple, but the answer is one of the cornerstones of your e-commerce success. While poorly managed consumable processes eat away at your profit, the right strategy elevates your brand.

You didn't start a business to deal with packing tape orders, warehouse cleaning, or "out of bubble wrap" crises. You set out to grow your brand, expand into global markets, and offer great products to your customers.

As OPLOG, with our proprietary technology, robotic infrastructure, and flexible business model, we remove consumable management and all your logistics processes from being a problem and transform them into a competitive advantage.

Are you ready to get rid of your operational burdens and enjoy the growth?